|

This book (Practical Electron Microscopy and Database) is a reference for TEM and SEM students, operators, engineers, technicians, managers, and researchers.

|

=================================================================================

Table 2429. Bond-pad contamination in IC devices induced during wafer-grinding.

Contaminant |

Contamination sources |

Effects |

Carbon |

Introduced during the process of backside grinding, through

pad opening process [e.g. Figure 2429] |

Induce non-sticking bond pad |

Result in ball lift |

Oxygen |

Introduced during backside grinding process or pad opening process (e.g. formed AlxFyOz), by reactive epoxy diluents, or by package paper during shipping (e.g. containing Al, F, O, and K) [e.g. Figure 2429] |

|

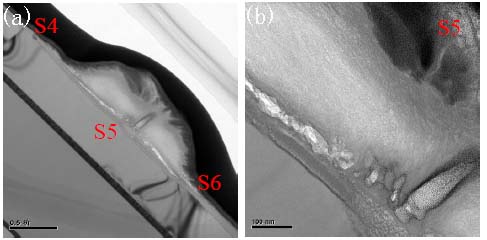

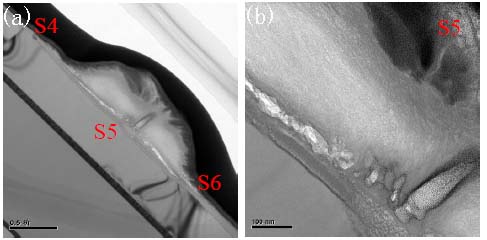

Figure 2429 shows an example of C, O, and Si contaminated bond pads. Area S6 had an abnormal film on the native Al oxide, while area S5 presented nonhomogeneous, loose and empty SixAlyCzOm materials in the hemispherical defect. These pad defects existed only at wafer edge because backside grinding was the root cause of the contamination.

Figure 2429. Contaminated bond pads. Adapted from [1]

[1] Paul Yu, Jamie Su, Qiang Gao, Ming Li, Chorng Niou, Study of Aluminum Pad Contamination Sources during Wafer Fabrication, Shipping, Storage and Assembly, International Symposium on High Density packaging and Microsystem Integration, 2007. HDP '07.

|