=================================================================================

The incident electron beam can be considered as made of a set of incident rays within an incident cone. In two-beam condition, the resulting pattern located in the back focal plane consists of two disks but not of two spots, namely the transmitted and hkl diffracted disks as shown in Figure 3883a (a). Given the strength of the objective lens is unchanged, when the defocus is changed from zero to Δh by adjusting the height of the TEM sample, the transmitted and diffracted beams in the diffraction pattern in the back focal plane will be changed from Figure 3883a (a) to (b). In this case, the diffraction spots in the image plane also move. Assuming the strengths of the other lenses in the TEM system are not changed, the diffraction pattern on the TEM screen or detector will be very different from the cases in Figure 3883a (a) to (b). If you are working on TEM-imaging mode, the TEM image will also be very different.

Figure 3883a. TEM optics under conditions of focused (a) and defocused (b) convergent incident electron beams.

Defocus CBED using high-index reflections provides a more accurate determination method of displacement vectors (R) of stacking faults than two-beam method with exciting low-index reflections, selected area electron diffraction method with low index reflections, and HRTEM technique. [1]

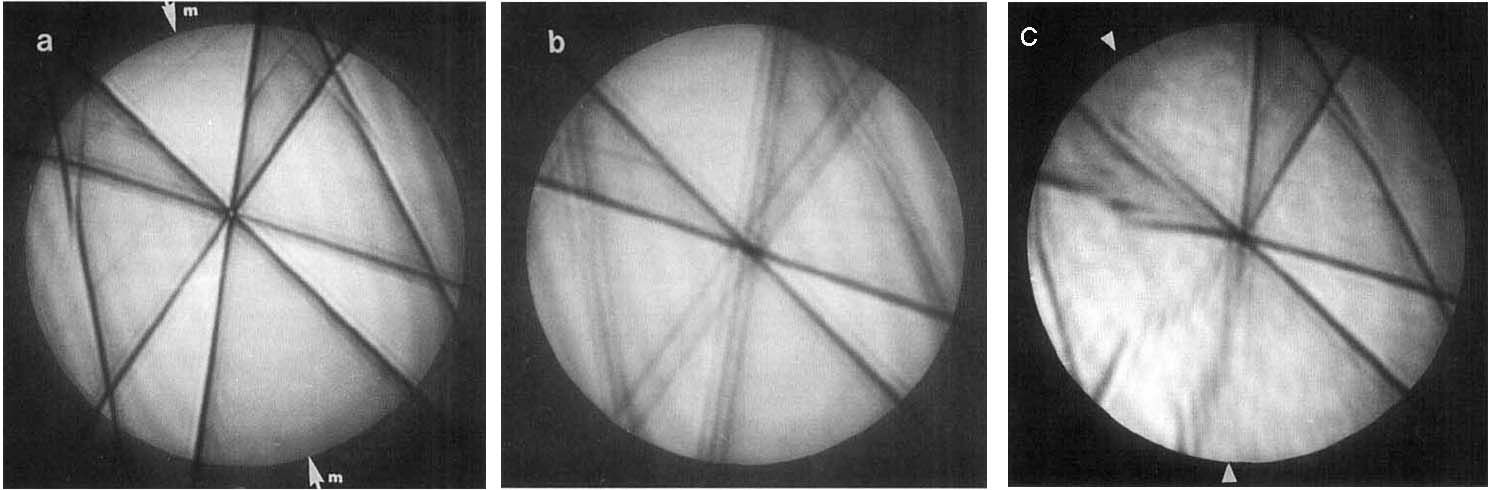

Figure 3883b shows the bright-field discs of convergent electron beam patterns obtained from an Fe-3ONi-19Cr alloy, with an incident beam along <114> axis and beam diameter of ~200 Å at 100 kV. The <114> projection of conventional CBED pattern in the perfect region (shown in Figure 3883b (a)) has a {110} mirror (m) along the arrowed direction, consisting with the pattern of HOLZ deficiency. However, as shown in Figure 3883b (b) the mirror is broken at the dislocation region with the deficiency lines displaced, indicating more information. The CBED pattern is a sensitive function of the distance of the probe from the dislocation and the probe size. The LACBED pattern shown in Figure 3883b (c) was obtained by a defocussed probe covering a 1-µm area across a specimen region, containing the same dislocation. The dislocation crosses various displaced deficiency lines, split into a number of subsidiary peaks. These features can be interpreted by a standard kinematic approach. [2]

Figure 3883b. Bright-field discs of convergent electron beam patterns obtained from an Fe-3ONi-19Cr alloy, with an incident beam along <114> axis and beam diameter of ~200 Å at 100 kV: (a): Conventional CBED taken from a region of perfect crystal; (b) Conventional CBED near a single dislocation; and (c) LACBED from an extended region including the same dislocation (The approximate position of the dislocation is arrowed.) Adapted from [2]

[1] Susumu Yamada and Michiyoshi Tanaka, Structure of a stacking fault in the (-101) plane of TiO2, Journal of Electron Microscopy 1: 67-74 (1997).

[2] Cherns D, and Preston A. R., Convergent beam diffraction studies of interfaces, defects, and multilayers, J Electron Microsc Tech. 1989 Oct;13(2):111-22.

|