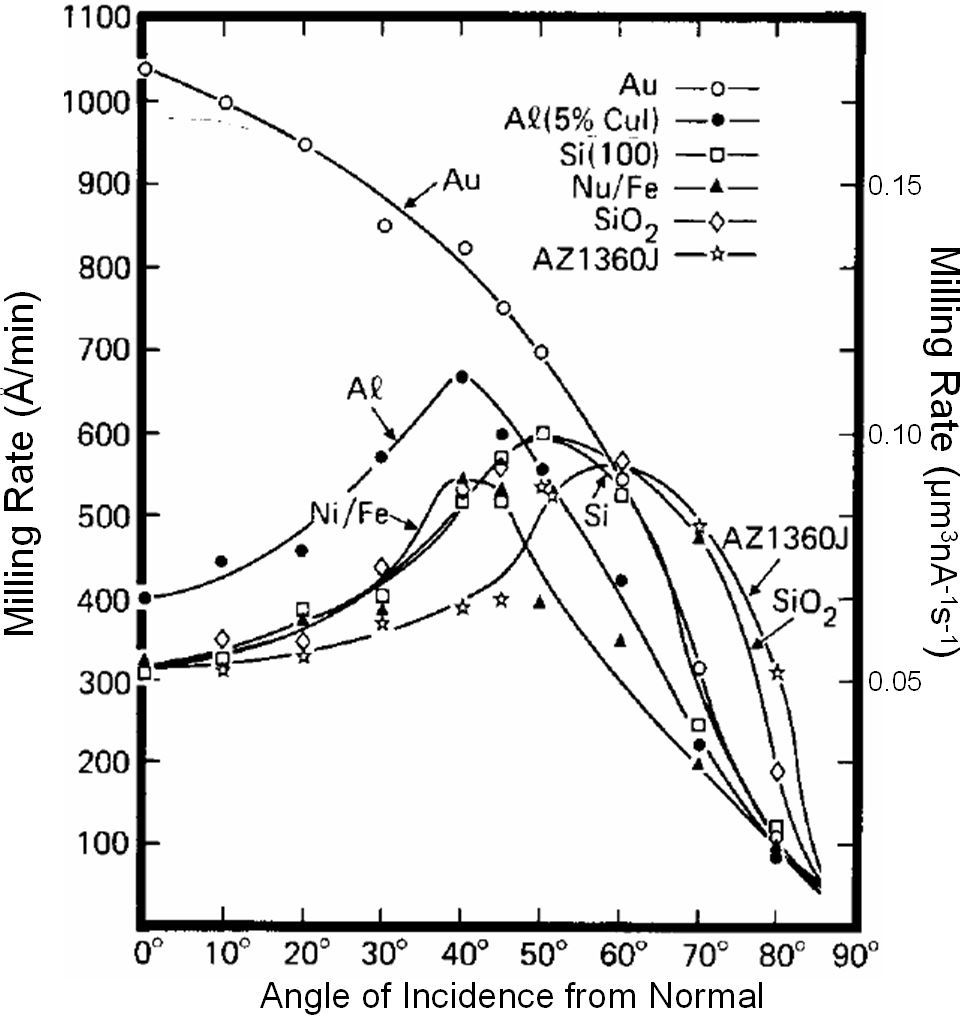

Figure 1309 shows the ion milling rate versus angle at a flux of 1 mA/cm2 750 eV argon (Ar) ions.

| Figure 1309. Ion milling rate versus angle at a flux of 1 mA/cm2 750 eV argon ions. Adapted from [5] |

Table 1309. Examples of milling rates of different materials with Ar ion polishing. The incident angle is the angle of incidence with respect to target normal.

| Sputtered material |

Milling rate

(µm3nA-1s-1 ) |

Total Yield (Atoms/Ion) |

| Beam energy: 2 kV and incident angle: 30° |

| Si |

0.0778 |

|

| Beam energy: 2 kV and incident angle: 15° |

| Si |

0.01667 [1] |

|

| Beam energy: 900 V and incident angle: 15° |

| Si |

0.0138 [1] |

|

| Beam energy: 500 V and incident angle: 15° |

| Si |

0.0041667 [1] |

|

| Beam energy: 500 V and incident angle: 0° |

| Ag |

0.366667 [3], 0.3 [4] |

|

| Al |

0.1216667 |

|

| Al2O3 |

0.01667 [3] |

|

| Au |

0.28333 [3], 0.18 [4] |

|

| Be |

0.028333 |

|

| C |

0.00733 |

|

| CaHNaO2 |

0.04875 |

|

| CdS |

0.38333 |

|

| Co |

0.091667 |

|

| Cr |

0.096667 [3], 0.08833 [4] |

|

| Cu |

0.183333 |

|

| Dy |

0.183333 |

|

| Er |

0.163333 |

|

| Fe |

0.088333 |

|

| GaAs (110) |

0.266667 |

|

| GaP (111) |

0.266667 |

|

| GaSb (111) |

0.316667 |

|

| Gd |

0.183333 |

|

| Ge |

0.166667 |

|

| Hf |

0.11 |

|

| InSb |

0.25 |

|

| Ir |

0.1 |

|

| LiNbO3 |

0.06667 |

|

| MgO |

0.02667 |

|

| Mo |

0.09 |

|

| Mo2C |

0.048333333 |

|

| Nb |

0.073333333 |

|

| Ni |

0.11 |

|

| Os |

0.085 |

|

| PbTe |

0.633333333 |

|

| Pd |

0.21667 |

|

| Pt |

0.14667 [3] |

|

| Re |

0.08667 |

|

| Rh |

0.12333 |

|

| Ru |

0.10167 |

|

| Si |

0.06333 [3] |

|

| SiC (0001) |

0.058333333 |

|

SiO2 |

0.0667, 0.065 [3], 0.0617 [4] |

|

| Sm |

0.183333333 |

|

| Sn |

0.3 |

|

| Ta |

0.07 |

|

| Th |

0.136666667 |

|

| Ti |

0.063333333 |

|

| U |

0.123333333 |

|

| V |

0.061666667 |

|

| W |

0.063333333 |

|

| Y |

0.16 |

|

YBa2Cu3O7 |

0.075 |

|

| ZnS |

0.1219 |

|

| Zr |

0.103333333 |

|

| Beam energy: 400 V and incident angle: 0° |

YBa2Cu3O7-x

|

0.008667

[2] |

|

| Beam energy: 200 V and incident angle: 0° |

| Ag |

0.166666667 |

|

| Al |

0.048333333 |

|

| Au |

0.118333333 |

|

| Be |

0.008666667 |

|

| C |

0.002166667 |

|

| CdS |

0.183333333 |

|

| Co |

0.043333333 |

|

| Cr |

0.055 |

|

| Cu |

0.088333333 |

|

| Dy |

0.096666667 |

|

| Fe |

0.043333333 |

|

| GaAs (110) |

0.13 |

|

| GaP (111) |

0.115 |

|

| GaSb (111) |

0.15 |

|

| Gd |

0.091666667 |

|

| Ge |

0.081666667 |

|

| Hf |

0.051666667 |

|

| InSb |

0.126666667 |

|

| Ir |

0.043333333 |

|

| Mo |

0.04 |

|

| Nb |

0.03 |

|

| Ni |

0.051666667 |

|

| Os |

0.033333333 |

|

| PbTe |

0.266666667 |

|

| Pd |

0.1 |

|

| Pt |

0.065 |

|

| Re |

0.038333333 |

|

| Rh |

0.051666667 |

|

| Ru |

0.04 |

|

| Si |

0.026666667 |

|

| Sm |

0.085 |

|

| Sn |

0.141666667 |

|

| Ta |

0.033333333 |

|

| Th |

0.068333333 |

|

| Ti |

0.026666667 |

|

| U |

0.056666667 |

|

| V |

0.028333333 |

|

| W |

0.03 |

|

| Y |

0.075 |

|

| Zr |

0.045 |

|

| |

|

|

| * The angles are the angles from normal incidence. |

[1] Arda Genç, Phase Stability in Metallic Multilayers, Ohio State University, Dissertation, 2008.

[2] Roman Adam, Stefan Benacka, Stefan Chromik, Marian Darula, Vladimir Strbik, and Stefan Gazi, Ivan Kostic, Emil Pincik, YBa2Cu3O7-x Step-Edge Junctions Prepared on Sapphire Substrates with YSZ Buffer Layer, IEEE Transactions on Applied Superconductivity, 5 (2), 1995.

[3] Williams, K., Gupta, K. & Wasilik, M. Etch rates for micromachining processingpart II. J. Microelectromech. S. 12, 761–778 (2003).

[4] Commonwealth Scientific Corporation. Ion beam etch rates. Bulletin 137-78.

[5] CHAPTER 3 Topography Effects in Deposition and Etching.

|