Wavelength Dispersive X-ray Spectroscopy (WDXRF/WDS) - Practical Electron Microscopy and Database - - An Online Book - |

|||||

| Microanalysis | EM Book http://www.globalsino.com/EM/ | |||||

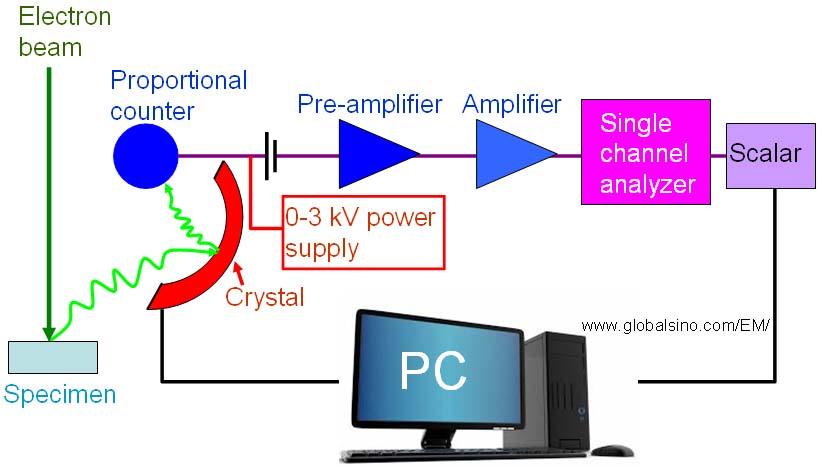

Wavelength dispersive X-ray spectroscopy (WDXRF/WDS) is less well known than EDS but is typically an addition to an existing EDS system. As shown in Figure 3813a, WDS uses crystal monochromators to disperse the emitted X-ray spectrum in terms of Bragg diffraction angle and thus wavelength. In other words, based on the Bragg's law, the collected X-rays are reflected off the crystal into a proportional counter so that WDS identifies and separates X-ray peaks. On the other hand, the X-rays that do not satisfy the Bragg criteria will be absorbed into the crystal or pass through it. Most SEM systems equipped with WDS have typically three or four crystals in order to analyze multiple elements with optimized performance in different wavelength ranges. Those crystal materials are often quartz, KAP, LiF, PbSt, PET and RAP.

Figure 3813a. Schematic illustration of a typical WDS system. Because the solid angle in a typical WDS is much smaller than that in EDS and the crystals must be scanned slowly to create a WDS scan, the measurement of WDS (using three or four crystals) is very slow, typically between 20 minutes and one hour for acquiring a single profile. However, different from EDS, it has high spectral resolution (e.g. 10 eV), good sensitivity to all elements (especially light elements), and better detection limit of ~ 0.005 %. The origin of high energy resolution is that only a small range of wavelengths is detected at a time resulting in great peak-to-background ratios, and high count rates for individual elements. The high count rates also give approximately 1 to 2 orders better sensitivity than that in EDS. WDS requires typically 10-100 times the electron beam current of EDS. WDS detectors have larger collection areas than other types of detectors (e.g. EDS detectors), but are located at longer distances from the specimen resulting in lower collection efficiencies. Furthermore, page2527 lists the comparison of various X-ray spectrometers, including lithium-drifted silicon (Si(Li)), Si-drift detectors (SDD), intrinsic-Ge (IG), wavelength dispersive X-ray spectroscopy (WDXRF/WDS), and Bolometer detectors. In general, WDS spectra can be converted into EDS spectra using the relation between wavelength and energy, The EDS profile of BaTiO3 system shown in Figure 3813b presents an example of EDS peak overlap. However, the FWHM of the WDS peaks is only a few eV because the energy resolution of the wavelength spectrometer is 5-10 eV. In this case, peak overlap in WDS is not a problem.

Since both the WDS system and the microscope share the same vacuum, there is no inlet window, and thus it is more suitable for low-energy/long-wavelength X-ray detection.

|

|

||||