=================================================================================

Two significant problems limit the application of titanium silicides (TiSi2) into Si devices: the C49-C54 phase transition temperature and the agglomeration of the silicide during the annealing processes.

The resistivities of the C49 phase and the C54 phase are very different as shown in Figure 146a so that to form low resistive contacts the phase transformation from C49 to C54 is very important. Figure 146a shows that the resistivity increases because of silicon diffusion into the metal as the temperature is increased from room temperature, while the resistivity reduces abruptly as C49 is formed, followed by further reduction to C54 phase. At temperatures above 900 °C the TiSi2 becomes discontinuous and the resistivity increases due to agglomeration.

Figure 146a. Dependence of phase and resistivity on annealing temperature.

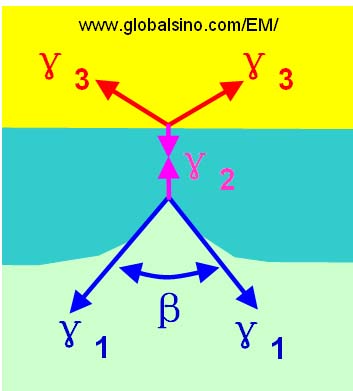

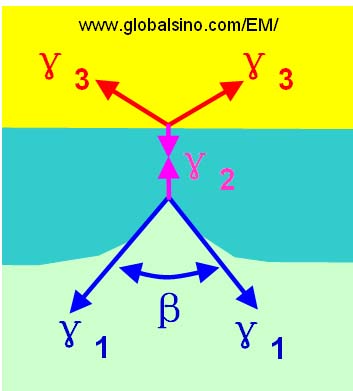

Figure 146b shows the schematic illustration of the surface and interfacial energies of the TiSi2/Si system. Morphological degradation of TiSi2 often referred to as agglomeration occurs as the TiSi2/Si system attempts to lower the overall energy of the system. If sufficient thermal energy is provided, silicon atoms diffuse through the silicide film and epitaxially precipitates out at grain boundaries, the silicide grains tend to spheroidize, and thus the film becomes discontinuous. The thermal stability of the system is in principle determined by the surface energy, interfacial energy, grain size, and film thickness. This problem particularly occurs in narrow lines that is less than or approximately the same dimension as the grain size.

Figure 146b. Schematic illustration of the surface and interfacial energies of the TiSi2/Si system.

Following Mullins [1, 2], Van den hove [3] suggested using the grain boundary grooving model to describe the thermal instability of TiSi2 films. In this model, the groove depth, d, is expressed as,

-------------- [146] -------------- [146]

where,

β -- The groove angle (See Figure 146b),

DSi -- The diffusivity of Si

in TiSi2,

γS -- The silicide/silicon interface energy,

Ω -- The atomic

volume of silicon,

C0 -- The equilibrium concentration of

silicon in TiSi2,

n -- The integers: 3 for bulk diffusion or 4 for interface

diffusion,

t = time,

T = temperature,

k --

Boltzmann’s constant.

When d becomes equivalent to the film thickness, the silicide becomes discontinuous. Because the grain-boundary grooving mechanism includes silicon diffusion through the silicide, the use of a nitrogen atmosphere during thermal annealing is essential in preventing this agglomeration failure mechanism.

[1] W. W. Mullins, “Theory of Thermal Grooving,” J. Appl.

Phys. 28, 333-339 (1957).

[2] W. W. Mullins, “Grain Boundary Grooving by Volume Diffusion,” Trans. Metall. SOC. 218, 354-361 (1960).

[3] L. Van den hove, “Advanced Interconnection and Contact

Schemes Based on TiSi, and CoSi,: Relevant Materials

Issues and Technological Implementation,” Ph.D. Thesis,

Katholieke Universiteit Leuven, Leuven, Belgium, 1988..

|

-------------- [146]

-------------- [146]