| In situ chemical processes in TEMs can be performed using dedicated TEM specimen holders. For instance, Creemer et al. [1] reported that a nanoreactor enabled high-resolution ETEM of nanomaterials during exposure to heat and gases at ambient pressure. The nanoreactor allowed the observation of nanocrystal growth and mobility of Cu/ZnO catalysts. The nanoreactor was a structure with microelectromechanical system (MEMS) and was functionalized with a micrometer-sized gas-flow channel, two electron-transparent windows, a heating device, and a thermal sensor. A drawback can be that the resolution of the HRTEM images is degraded by the extra scattering of the electron beam on gas atoms and electron-transparent windows, and by specimen drift due to heating. This drawback can be suppressed as the number of the gas atoms is reduced by limiting the gas pressure or by confining the gas along the electron beam into a layer that is as thin as possible. Confinement has been achieved by two ways: differentially pumped vacuum systems [2–5] and windowed cells [1,6–7].

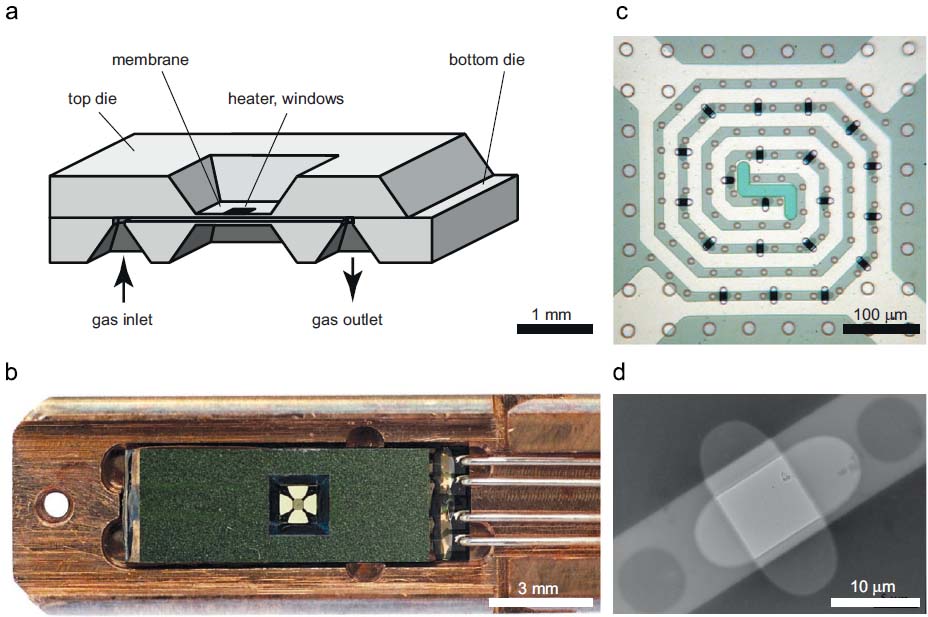

The technique of windowed cells allows a much thinner gas layer than that in a differentially pumped system. In the technique of windowed cells, high atomic-scale resolution can be obtained at applicable gas pressures from ~ 1 x 10-2 to 1.2 bar and temperatures of up to several hundred degrees Celsius [1, 2, 4–7]. For instance, Figure 2571 shows the MEMS-structured nanoreactor presented by Creemer et al. [1] The nanoreactor was composed of two facing dies made with thin-film technology on silicon (Si) substrates. Some considerations need to be taken into account:

i) The gas layer is up to 5 mm thick, corresponding to a gas density of 3 x 103 atoms/nm2 at the beam location [8].

ii) Each die has a central hole of 1 mm2 that is covered by a 1.2 µm thick SiNx membrane. A window consists of a thin SiNx film (e.g. 10 nm in thickness) [9]. The SiNx is amorphous to avoid the effect of electron diffraction contrast. The windows must withstand a necessary pressure with respect to the vacuum in the TEM column. The theoretical lateral dimension of the thin window is thus limited to about 10 µm and to ellipsoidal shape [10,11].

iii) The minimum height of the shallow gas-flow channel is 4 µm, determined by disc-shaped spacers integrated in one of the membranes [1], as shown in Figure 2571 (c). The spacers prevent stiction of the membranes in order to avoid permanently blocking the channel.

iv) In the areas between the two windows, the heater is an embedded, spiral, and thin Pt wire as shown in Figure 2571 (c) [12, 13]. The wire is protected on all its sides by SiNx and can be resistively heated up to 500 °C during TEM observations [14,15]. The heated gas volume is small, resulting in low power consumption as well as small thermal expansion of the system components so that limiting the specimen drift. The temperature of the window area can be extracted from the local electrical resistance, which is measured through the four electrical connections, based on temperature coefficient of resistance (TCR) theory, in an uncertainty of 10%. Four tungsten probe needles electrically connect with the heater and thermal sensor.

v) For operation in a TEM, the nanoreactor is mounted on a custom-made TEM specimen holder as shown in Figure 2571 (b). The nanoreactor is connected with two sealed tubes to introduce a flowing gas phase.

vi) The tip of the holder has a limited thickness, e.g. ~3.6 mm. [1]

Figure 2571. (a) Schematic illustration of the nanoreactor device for in situ TEM chemical processes. (b) Optical photo of the TEM holder with the integrated nanoreactor and the four electrical probe contacts. (c) Optical zoom-in photo of the nanoreactor membrane. The bright spiral is the Pt heater, while the small ovaloids are the electron-transparent windows. The circles are SiO2 spacers that define the minimum height of the gas channel. (d) A low-magnification TEM image of a pair of superimposed 10 nm thick windows.

[1] J. F. Creemer, S. Helveg, G.H. Hoveling, S. Ullmann, A.M. Molenbroek, P.M. Sarro a, H.W. Zandbergen, Atomic-scale electron microscopy at ambient pressure, Ultramicroscopy 108 (2008) 993 – 998.

[2] E.P. Butler, K.F. Hale, Dynamic Experiments in the Electron Microscope,

Practical Methods in Electron Microscopy, vol. 9, North-Holland, Amsterdam,

1981.

[3] R.T.K. Baker, P.S. Harris, J. Phys. E 5 (1972) 793.

[4] E.D. Boyes, P.L. Gai, Ultramicroscopy 67 (1997) 219.

[5] R. Sharma, P.A. Crozier, Environmental Transmission Electron Microscopy in

Nanotechnology, Microscopy in Nanotechnology, Kluwer Academic, New

York, 2005.

[6] G.M. Parkinson, Catal. Lett. 2 (1989) 303.

[7] S. Giorgio, S. Sao Joao, S. Nitsche, D. Chaudanson, G. Sitja, C.R. Henry,

Ultramicroscopy 106 (2006) 503.

[8] P.L. Hansen, S. Helveg, A.K. Datye, Adv. Catal. 50 (2006) 77.

[9] P.J. French, P.M. Sarro, R. Malle´ e, E.J.M. Fakkeldij, R.F. Wolffenbuttel, Sensors

Actuators A 58 (1997) 149.

[10] J. Yang, O. Paul, Sensors Actuators A 97–98 (2002) 520.

[11] C. van Rijn, M. van der Wekken, W. Nijdam, M. Elwenspoek, J. Microelectromech.

Syst. 6 (1997) 48.

[12] D. Briand, A. Krauss, B. van der Schoot, U.Weimar, N. Barsan,W. Go¨ pel, N.F. de

Rooij, Sensors Actuators B 68 (2000) 223.

[13] F. Solzbacher, C. Imawan, H. Steffels, E. Obermeier, M. Eickhoff, Sensors

Actuators B 77 (2001) 111.

[14] D. Briand, F. Beaudoin, J. Courbat, N.F. de Rooij, R. Desplats, P. Perdu,

Microelectron. Reliab. 45 (2005) 1786.

[15] S.L. Firebaugh, K.F. Jensen, M.A. Schmidt, J. Microelectromech. Syst. 7 (1998)

128.

|