The principle of semiconductor detectors is based on solid-state physics.

|

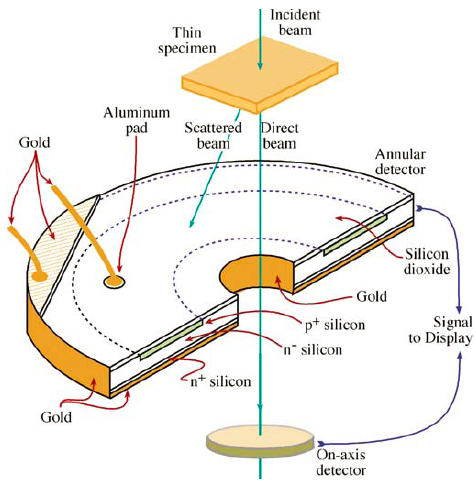

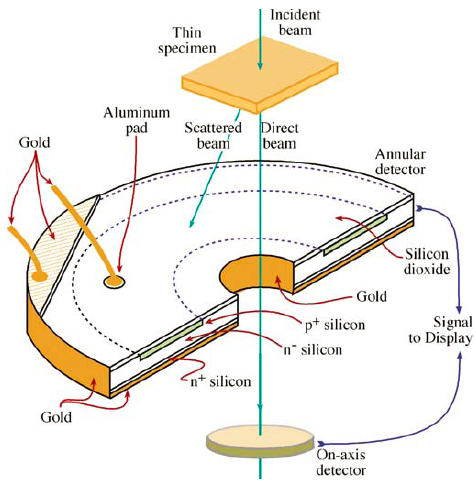

| Figure 4996 (a). Semiconductor detector of the surface-barrier type, shown in

a configuration where it would be used to detect high-energy, forward scattered

electrons (e.g. for TEM in this figure). The direct beam is detected by a small circular detector

on the optic axis of the microscope surrounded by a concentric wide-angle

annular detector (e.g. for HAADF imaging), which detects any scattered electrons. |

|

| Figure 4996 (b). Electron-hole pairs induce electrical current. |

The semiconductor detector, shown schematically in Figure 4996 (a), is a doped single-crystal sheet of Si (often

inaccurately described as a solid-state detector). We

make the Si into an electron-sensitive detector by creating

a p-n junction beneath the Si surface in one of two

ways. In one type of detector, we create the junction by

doping the Si (e.g., by ion implantation of n-type impurity

atoms into p-type Si or vice versa). This doping

disturbs the equilibrium charge carrier concentration

and creates a region across the p-n junction that is free

of majority carriers which we call a ‘depletion region.’ A

conducting metal layer is evaporated onto both surfaces

to provide ohmic contacts. The alternative type of detector

is called a surface-barrier detector (or sometimes a

Schottky diode) and we fabricate this by evaporating a

thin layer of Au on the surface of high-resistivity n-type

Si, or evaporating Al onto p-type Si. This surface layer

acts as an electrical contact and also creates a depletion

layer and a p-n junction just inside the Si. When we put either of these detectors into a beam of

high-energy electrons, most of the beam energy is transferred

to valence-band electrons in the Si which are

excited across the band gap into the conduction band

thus creating electron-hole pairs (see Figure 4996 (b)). We

can separate the electrons and holes most efficiently by

applying an external reverse bias to the detector; that is,

we put a negative bias on the p side of the junction and a

positive bias on the n side. In practice, however, so many

electron-hole pairs are created at TEM beam energies that an external bias is not usually necessary, and the

internal bias of the p-n junction acts to separate the

electrons and holes. Because the electrons and holes

move quite quickly in Si, it takes only a few nanoseconds

to gather most of the carriers over an area of ~ 1 µm2. So

the semiconductor detector is remarkably responsive to

electrons. The net result is that the incoming electron

signal is converted to a current in the external circuit

between the surface contacts, as shown in the surface barrier

detector in Figure 4996 (a).

Since it takes approximately 3.6 eV to produce an

electron-hole pair in Si at room temperature, a 100-keV

electron can theoretically produce ~28,000 electrons.

This represents a maximum detector gain of close to

3 x 104 but in practice there are losses due to electron

absorption in the metal contact layer and recombination

of the electrons and the holes close to the Si surface

(in a region called the dead layer), and we actually get a

gain of closer to 2x104.

These semiconductor detectors are very efficient at

picking up and amplifying electron signals. Unfortunately,

they have an inherently large capacitance, so

they are not very responsive to rapid changes in signal

intensity. Such changes are quite likely to occur during

the rapid scanning process of STEM imaging. In other

words, the detector has a narrow bandwidth (typically

100 kHz); this is not a good property for a detector which is subject to widely varying signal intensities.

We could lower the capacitance by decreasing the detector

area, but if we do this, the signal-to-noise ratio will

be lowered. It is the S/N ratio that ultimately limits the

quality of all scanning images.

Semiconductor detectors have several advantages

* We can easily fabricate them.

* They are cheap to replace.

* They can be cut into any shape, as long as it is flat.

This latter advantage makes them ideal for squeezing

into the confines of TEM stages and columns. For

example, we can make the semiconductor detector in

annular form so that the main electron beam goes

through the hole in it, but the scattered electrons are

very efficiently detected. This produces a dark-field

(scattered electron) detector. We can also make detectors

that are divided into halves or quadrants and each

segment is insulated from the other(s). These detectors

are very useful for discriminating directional signals

such as those coming from magnetic specimens.

There are also some drawbacks to semiconductor

detectors & They have a large dark current (the current registered

when no signal is incident on the detector).

This dark current arises from thermal activation of

electron-hole pairs, or from light falling on an uncoated detector. Since the detectors in a TEM

invariably have a metal ohmic contact, the light

problem is minimal because light can’t penetrate

the metal film.

Now we could minimize thermal

activation by cooling the detector to liquid-nitrogen

temperatures but that step is impractical and introduces

a cold surface into the vacuum which would

simply collect contamination, so we live with noise

due to the thermal activation.

* Because noise is inherent in the semiconductor

detector, its DQE is poor for low-intensity signals,

but rises almost to unity for high-intensity

signals.

* The electron beam can damage the detector, particularly

in intermediate voltage microscopes. In these

circumstances, a doped p-n detector is less sensitive

than a surface-barrier detector, because the depletion

region is deeper in the Si.

* They are insensitive to low-energy electrons such as

secondary electrons.

Despite these drawbacks, both types of Si detector

are far more robust than the alternative scintillator.

|